There are a variety of factors that go into the construction of an expansion joint. The three major categories of expansion joint are defined by the operating conditions the parts are subject to.

SPOOL JOINTS IN DEPTH

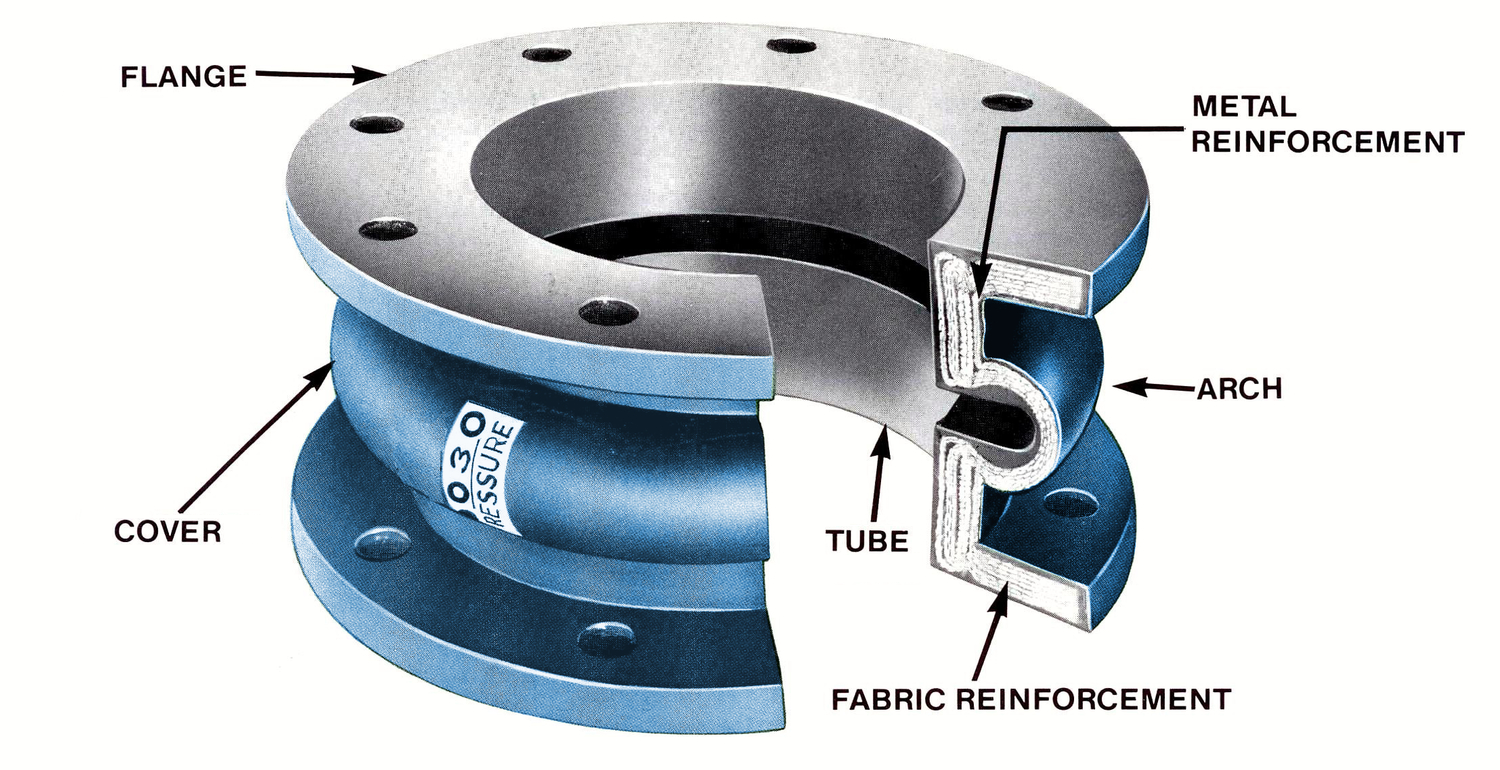

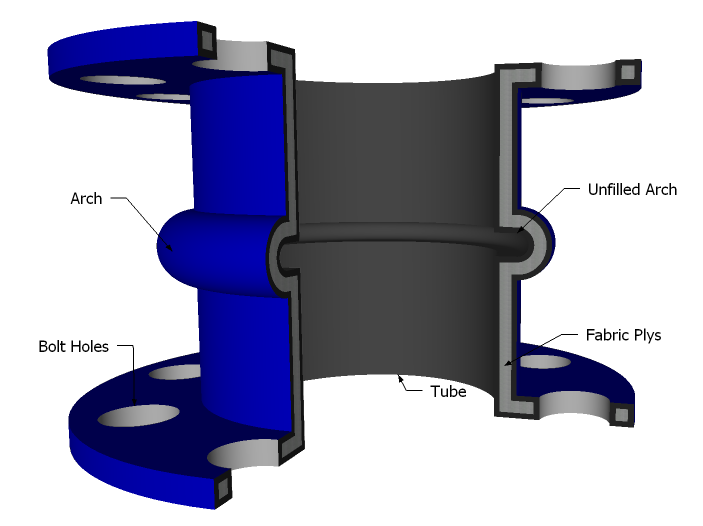

Tube & Liners

The protective, seamless, leak-proof inner lining of La Favorite rubber expansion joints prevents corrosives and abrasive elements from reaching the inner carcass of the joint. Lining selection is dependent on service conditions which should be known before ordering. Our sales department can make proper recommendations concerning lining selection. Available materials include but are not limited to Chlorobutyl, Neoprene, Buna N, and EPDM.

Fabric Reinforcement

Located between the tube and cover, the fabric provides strength for the joint. It is composed of multiple plies of high strength fabric, impregnated with rubber. It is then vulcanized into a strong tough carcass.

Metal Reinforcement

All standard joints are reinforced with steel to provide strength under high operating pressures. Smaller sizes use spiral wound wire while the larger units employ endless steel rings. All steel reinforcement is embedded in the carcass of the joint and therefore protected from corrosives.

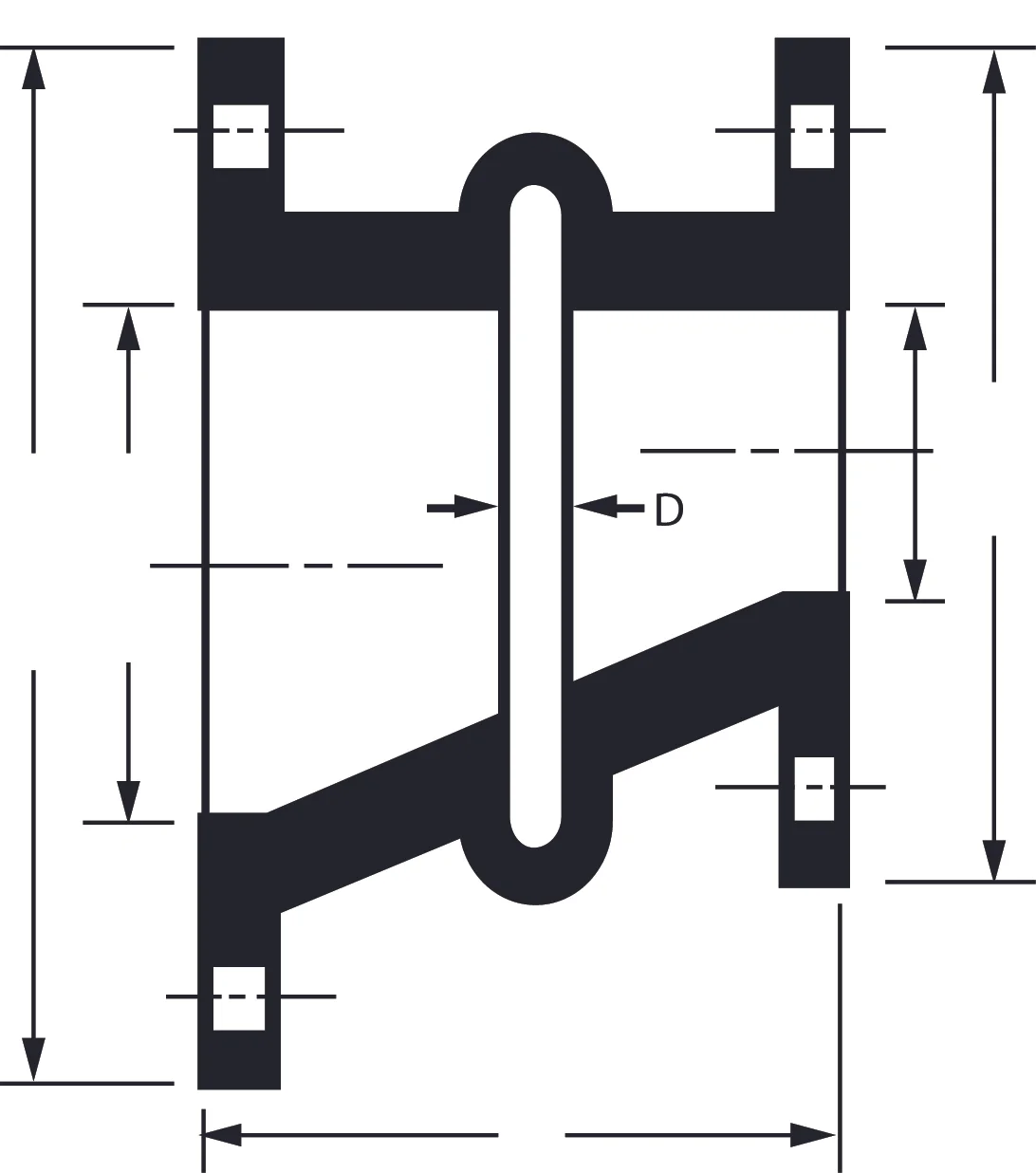

The Arch - Filled or Unfilled

The convolution or corrugation, known commonly as the arch, is what allows the expansion joint to absorb movements. Standard construction calls for an unfilled or open arch. This provides the joint with maximum movement capability. In some cases, a filled arch is specified, where the flowing medium, usually slurry, may clog an open arch. Construction of filled arch joints is similar to standard joints except that the arch space is occupied by a soft rubber filler which is protected by the tube, giving the joint a smooth bore. Movement capability is reduced by 50% with a filled arch and must be taken into account when ordering.

Face to Face (Length)

The face to face dimension is the distance between the two flanges. Although standards have been established for this dimension, it is not an absolute. La Favorite can custom furnish expansion joints in almost any face to face dimension, depending on your individual installation requirements.

The Cover

This outer skin protects the carcass of the joint in much the same way as the tube does. All La Favorite joints use neoprene as a standard cover material. Neoprene provides maximum protection against the effects of weathering and ozone.

The Flange

The smooth durable rubber facing of the flange forms a tight seal with the companion flange, thereby eliminating the need for gaskets. The inner flange structure is of multiple fabric plies that are integral with the body. The bolt holes are completely surrounded by fabric, which insures against tears or blowouts and are sealed to prevent wicking.

Styles

Style 9030 - Pressure

These are the base La Favorite design suitable to resist pressure conditions resulting from the majority of circulating water circumstances.

Style 9060 - Pressure and Vacuum

Style 9060 design expansion joints are designed and built to not only resist a pressure environment but also any vacuum conditions that can often occur based on their position placement in regards to pumps.

Style 9090 - U.S. Navy Style Expansion Joints

Used extensively aboard Navy ships, the style 9090 is similar in configuration to the standard spool type, except that strict material specifications for fire retardancy are adhered to. In addition, Navy flanges and drilling are different from standard commercial flanges. La Favorite expansion joints have been installed on many U.S. Navy combat and support vessels and because of their high quality, have been specified for use on the world's largest nuclear powered aircraft carriers.

Variations of any of the above mentioned styles are available to address specific system and condition needs.

In a perfect world "standard construction" would always work. The reality is, this isn't always the case. Piping can shift and move over time due to usage conditions. Older components are changed out with newer, more efficient equipment creating different and unique connectivity issues. La Favorite Industries excels in the design and construction of unique spool expansion joints for a wide range of customer applications. We work closely with our customers to address their situation and formulate a solution.